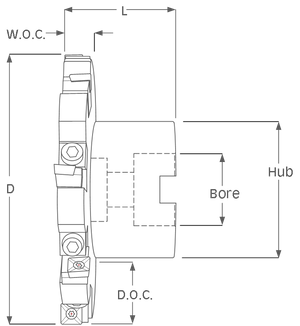

Shell Mount Slotting Cutters / Half Side Mills

4.000 - 10.000 Diameter

- K-Tool, Inc. slotting cutters will ship direct from the factory.

- All cutters will be preset at no charge using an indicator to ensure accuracy.

- Choose from the options below when ordering.

- - Full Slot - specify W.O.C. when ordering (.250 - 1.187)

- - Half Side Mill - Specify L.H. or R.H. when ordering

- (please allow 1 - 2 business days for shipping)

| Tool Info. Shell Mount Style Slotting Cutter |

||||||||||||||

| Series #00 / .250 - .340 W.O.C. | ||||||||||||||

| Tool # | D | Flutes | W.O.C. | D.O.C. | Bore | Key | Hub | L | Cartridge | Wedge | Wedge Screw | Insert | Insert Screw | Wrench |

| SCSM-4000 | 4.000 | 10 | .250 - .340 | .875 | 1.000 | .375 | 2.000 | 1.625 | 1511C-RH/LH | 1 Wedge | 6 | SPEB-1511CB | 164T | T-6 |

| SCSM-5000 | 5.000 | 12 | 1.062 | 1.250 | .500 | 2.625 | 1.750 | |||||||

| SCSM-6000 | 6.000 | 14 | 1.562 | 1.250 | .500 | 2.625 | 1.750 | |||||||

| Series #0 / .340 - .430 W.O.C. | ||||||||||||||

| Tool # | D | Flutes | W.O.C. | D.O.C. | Bore | Key | Hub | L | Cartridge | Wedge | Wedge Screw | Insert | Insert Screw | Wrench |

| SCSM-400 | 4.000 | 10 | .340 - .430 | .875 | 1.000 | .375 | 2.000 | 1.625 | 222C-RH/LH | 2 Wedge | 8 | SPEB-220P SPEB-221P SPEB-222P |

314T | T-8 |

| SCSM-500 | 5.000 | 12 | 1.062 | 1.250 | .500 | 2.625 | 1.750 | |||||||

| SCSM-600 | 6.000 | 14 | 1.562 | 1.250 | .500 | 2.625 | 1.750 | |||||||

| Series #1 / .430 - .530 W.O.C. | ||||||||||||||

| Tool # | D | Flutes | W.O.C. | D.O.C. | Bore | Key | Hub | L | Cartridge | Wedge | Wedge Screw | Insert | Insert Screw | Wrench |

| SCSM-401 | 4.000 | 8 | .430 - .530 | .875 | 1.000 | .375 | 2.000 | 1.625 | 2522C-RH/LH | 3 Wedge | 10 | SPEB-2521P SPEB-2522P |

314T | T-8 |

| SCSM-501 | 5.000 | 10 | 1.062 | 1.250 | .500 | 2.625 | 1.750 | |||||||

| SCSM-601 | 6.000 | 12 | 1.000 | 1.500 | .625 | 3.800 | 2.250 | |||||||

| SCSM-801 | 8.000 | 16 | 1.975 | 1.500 | .625 | 3.800 | 2.250 | |||||||

| Series #2 / .530 - .687 W.O.C. | ||||||||||||||

| Tool # | D | Flutes | W.O.C. | D.O.C. | Bore | Key | Hub | L | Cartridge | Wedge | Wedge Screw | Insert | Insert Screw | Wrench |

| SCSM-402 | 4.000 | 8 | .530 - .687 | .875 | 1.000 | .375 | 2.000 | 1.625 | 332C-RH/LH | 3 Wedge | 10 | SPEB-331P SPEB-332P |

538T | T-10 |

| SCSM-502 | 5.000 | 10 | 1.062 | 1.250 | .500 | 2.625 | 1.750 | |||||||

| SCSM-602 | 6.000 | 12 | 1.000 | 1.500 | .625 | 3.800 | 2.250 | |||||||

| SCSM-802 | 8.000 | 16 | 1.975 | 1.500 | .625 | 3.800 | 2.250 | |||||||

| Series #3 / .687 - .937 W.O.C. | ||||||||||||||

| Tool # | D | Flutes | W.O.C. | D.O.C. | Bore | Key | Hub | L | Cartridge | Wedge | Wedge Screw | Insert | Insert Screw | Wrench |

| SCSM-403 | 4.000 | 8 | .687 - .937 | .875 | 1.000 | .375 | 2.000 | 1.625 | 432C-RH/LH | 3 Wedge | 10 | SPEB-431PA SPEB-432PA |

638T | T-15 |

| SCSM-503 | 5.000 | 10 | 1.062 | 1.250 | .500 | 2.625 | 1.750 | |||||||

| SCSM-603 | 6.000 | 12 | 1.000 | 1.500 | .625 | 3.800 | 2.250 | |||||||

| SCSM-803 | 8.000 | 16 | 1.975 | 1.500 | .625 | 3.800 | 2.250 | |||||||

| Series #4 / .937 - 1.187 W.O.C. | ||||||||||||||

| Tool # | D | Flutes | W.O.C. | D.O.C. | Bore | Key | Hub | L | Cartridge | Wedge | Wedge Screw | Insert | Screw | Wrench |

| SCSM-504 | 5.000 | 6 | .937 - 1.187 | 1.062 | 1.250 | .500 | 2.625 | 1.750 | 532C-RH/LH | 4 Wedge | 5161D | SPEB-532PA | 838T | T-20 |

| SCSM-604 | 6.000 | 8 | 1.012 | 1.500 | .625 | 3.625 | 2.250 | |||||||

| SCSM-804 | 8.000 | 12 | 1.975 | 1.500 | .625 | 3.800 | 2.250 | |||||||

45° Cartridges Available

for Series #1 & Series #3 Slotting Cutters

| 45° Cartridges Available for Series #1 & Series #3 Cutters |

||||||

| Series # | Cartridge | Wedge | Wedge Screw | Inserts | Insert Screw | Wrench |

| 1 | 2522C-45 | 3 Wedge | 10 | SPEB-2521P SPEB-2522P |

314T | T-8 |

| 3 | 432C-45 | 3 Wedge | 10 | SPEB-431PA SPEB-432PA |

638T | T-15 |

- Other Slotting Products :

- - Arbor Mount Slotting Cutters

- - T-Slot Cutters

- - T-Slot Key Cutters

- - Full Radius Slotting Cutters

- - Radius Slotting Mills

- K-Tool, Inc. has the capability of manufacturing slotting cutters up to a 20" max diameter

- Call us to discuss your application or email your information to info@ktoolinc.com

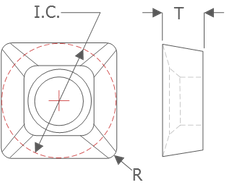

Insert Info.

| Insert Info. | ||||

| Insert # | I.C. | T | R | Grades |

| SPEB-1511CB | .187 | .082 | .015 | K11 / K22 |

| SPEB-220P | .250 | .125 | .002 - .004 | K11 |

| SPEB-221P | .250 | .125 | .015 | K11 |

| SPEB-222P | .250 | .125 | .031 | B1M / D66 / K11 / X40 |

| SPEB-2521P | .312 | .125 | .015 | K11 |

| SPEB-2522P | .312 | .125 | .031 | B1M / C55 / K11 / X40 |

| SPEB-331P | .375 | .187 | .015 | K11 |

| SPEB-332P | .375 | .187 | .031 | B1M / D66 / K11 / K22 |

| SPEB-431PA | .500 | .187 | .015 | X33 |

| SPEB-432PA | .500 | .187 | .031 | B1M / D66 / K11 / X40 |

| SPEB-532PA | .625 | .187 | .031 | C55 / K11 / K22 |

Technical Data

| Speed and Feed Info. Series #00 |

||

| Material | S.F.M. | I.P.T. |

| Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

800 - 1200 | .002 - .003 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .002 - .003 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .002 - .003 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .002 - .003 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .002 - .003 |

| Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .002 - .003 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

120 - 180 | .001 - .002 |

| Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

1000 - 2500 | .002 - .004 |

| Speed and Feed Info. Series #0 - Series #1 - Series #2 - Series #3 - Series #4 |

||

| Material | S.F.M. | I.P.T. |

| Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

800 - 1200 | .002 - .006 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .002 - .005 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .002 - .005 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .002 - .004 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .002 - .004 |

| Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .003 - .007 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

120 - 180 | .001 - .003 |

| Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

1000 - 2500 | .003 - .008 |

| Insert Grade Selection | ||

| Material | Material Examples | Preferred Grades |

| Mild & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | K11 or X33 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | K11 or X33 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | K11 or X33 |

| Tool Steels | A-2, A-6, D-2, M-2 | K11 or X33 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | K11 or X33 |

| Iron | Cast, Nodular | D66 or C55 / K11 |

| Iron | Ductile | K11 or X33 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | K11 or X33 |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | B1M / K11 or X33 / K22 or X40 |

| Insert Grade Description | ||

| Grade | Grade Description | |

| B1M | Uncoated Carbide | |

| C55 | Advanced Multi-Layer PVD Coated Carbide | |

| D66 | Multi-Layer Dense Coating | |

| K11 | Universal High Performance Dense Coating | |

| K22 | Ultra Smooth Dense Coating - No Hone | |

| X33 | High Performance Nitride | |

| X40 | Extremely Smooth Boride Coating / Periphery Ground | |