Insert Grade & Screw Technical Data

Insert Grade & Selection Info

| Insert Grade Selection | ||

| Material | Material Examples | Preferred Grades |

| High & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | K11 / X33 / A10M |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | K11 / X33 / A10M |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | K11 / X33 / A10M |

| Tool Steels | A-2, A-6, D-2, M-2 | K11 / X33 / A10M |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | K11 / X33 / A10M |

| Iron | Cast, Nodular | D66 / C55 |

| Iron | Ductile | K11 / X33 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | K11 / X33 / A10M |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | K22 / X40 / B1M / K11 / X33 |

| Insert Grade Info. | ||

| Grade | Description | Primary Use |

| A1M | TIN Coated | General Purpose Grade (Spot Drill Inserts Only) |

| B1M | Uncoated Carbide - No Hone | Plastic & Non Ferrous: Aluminum, Brass, Bronze |

| D66 | Multi-Layer Dense Coating | Cast Iron |

| K11 | Universal High Performance Dense Coating | General Purpose Grade |

| K22 | Ultra Smooth Dense Coating | Aluminum & Non-Ferrous Metal |

| The following grades will be replaced as stock is depleted | ||

| C55 | Replaced with D66 | Cast Iron |

| X33 | Replaced with K11 | General Purpose Grade |

| A10M | General Purpose Grade | |

| X40 | Replaced with K22 | Aluminum & Non-Ferrous Metal |

- To get the optimum life out of your inserts and maximize the efficiency of your cutter contact K-Tool, Inc. Tech Support for specific speed & feed recommendations based on your application.

- Phone#: 800-377-3056

- E-Mail: info@ktoolinc.com

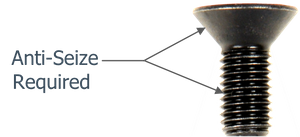

Insert Screw Information

- Insert screws are a very important part of the performance of indexable cutting tools.Insert screws are also the most overlooked when the tool or insert performance drops off. Worn or damaged screws can cause the inserts to seat incorrectly in the pocket. This condition can cause vibration, chatter, incorrect cutting diameters, poor finish, insert failure or even tool failure.

Important: Apply anti-seize to the screw threads and the bottom of the screw head

| Insert Screw Specifications | ||||

| Screw # | Thread | Wrench | Recommended Screw Torque |

Max Screw Torque |

| 164T | 1 - 64 | T-6 | 2.7 - 3.3 In. Lb. | 5.5 In. Lb. |

| 300T | 3 - 48 | T-8 | 5.7 - 6.8 In. Lb. | 11.3 In. Lb. |

| 314T | 3 - 48 | T-8 | 5.7 - 6.8 In. Lb. | 11.3 In. Lb. |

| 414T | 4 - 40 | T-10 | 10 - 11.9 In. Lb. | 19.9 In. Lb. |

| 438T | 4 - 40 | T-10 | 10 - 11.9 In. Lb. | 19.9 In. Lb. |

| 538T | 5 - 40 | T-10 | 10 - 11.9 In. Lb. | 19.9 In. Lb. |

| 560T | 5 - 40 | T-10 | 10 - 11.9 In. Lb. | 19.9 In. Lb. |

| 5625T | 5 - 40 | T-10 | 10 - 11.9 In. Lb. | 19.9 In. Lb. |

| 614T | 6 - 32 | T-15 | 15.3 - 18.3 In. Lb. | 30.5 In. Lb. |

| 638T | 6 - 32 | T-15 | 15.3 - 18.3 In. Lb. | 30.5 In. Lb. |

| 838T | 8 - 32 | T-20 | 22.8 - 27.4 In. Lb. | 45.6 In. Lb. |

| 1012T | 10 - 32 | T-25 | 33.6 - 40.4 In. Lb. | 67.3 In. Lb. |

| 1412T | 1/4 - 28 | 5/32 Allen | 77.4 - 92.9 In. Lb. | 154.9 In. Lb. |