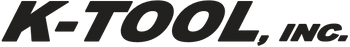

T-Slot / Key Cutters

- .250 - .312 - .375 - .500 - .625 - .750 W.O.C

- - Offset inserts for reduced tool pressure

- - Multi-Flute design for higher feed rates

| Tool Info. .250 W.O.C. |

|||||||||||

| Tool # | D | D-1 | B | Flutes | L | L-1 | L-2 | S | Insert | Screw | Wrench |

| TSK-7525 | .750 | .310 | .250 | 4 Flutes / 2 Effective | 2.750 | 1.000 | .900 | .500 | SPEB-1511CB | 164T | T-6 |

| TSK-1025 | 1.000 | .350 | .250 | 4 Flutes / 2 Effective | 3.250 | 1.250 | 1.050 | .750 | SPEB-1511CB | 164T | T-6 |

| TSK-1225 | 1.250 | .385 | .250 | 6 Flutes / 3 Effective | 3.250 | 1.250 | 1.066 | .750 | SPEB-1511CB | 164T | T-6 |

| TSK-1525 | 1.500 | .450 | .250 | 6 Flutes / 3 Effective | 3.250 | 1.250 | 1.100 | .750 | SPEB-1511CB | 164T | T-6 |

| TSK-2025 | 2.000 | .750 | .250 | 8 Flutes / 4 Effective | 4.000 | 2.000 | N/A | .750 | SPEB-1511CB | 164T | T-6 |

| TSK-2525 | 2.500 | .750 | .250 | 8 Flutes / 4 Effective | 4.000 | 2.000 | N/A | .750 | SPEB-1511CB | 164T | T-6 |

| TSK-3025 | 3.000 | 1.000 | .250 | 8 Flutes / 4 Effective | 4.500 | 2.250 | N/A | 1.000 | SPEB-1511CB | 164T | T-6 |

| Tool Info. .312 W.O.C. |

|||||||||||

| Tool # | D | D-1 | B | Flutes | L | L-1 | L-2 | S | Insert | Screw | Wrench |

| TSK-7531 | .750 | .310 | .312 | 4 Flutes / 2 Effective | 2.750 | 1.000 | .900 | .500 | SPEB-1511CB | 164T | T-6 |

| TSK-1031 | 1.000 | .350 | .312 | 4 Flutes / 2 Effective | 3.250 | 1.250 | 1.050 | .750 | SPEB-1511CB | 164T | T-6 |

| TSK-1231 | 1.250 | .450 | .312 | 6 Flutes / 3 Effective | 3.250 | 1.250 | 1.100 | .750 | SPEB-1511CB | 164T | T-6 |

| TSK-1531 | 1.500 | .500 | .312 | 6 Flutes / 3 Effective | 3.250 | 1.250 | 1.125 | .750 | SPEB-1511CB | 164T | T-6 |

| TSK-2031 | 2.000 | .750 | .312 | 8 Flutes / 4 Effective | 4.000 | 2.000 | N/A | .750 | SPEB-1511CB | 164T | T-6 |

| TSK-2531 | 2.500 | .750 | .312 | 8 Flutes / 4 Effective | 4.000 | 2.000 | N/A | .750 | SPEB-1511CB | 164T | T-6 |

| TSK-3031 | 3.000 | 1.000 | .312 | 8 Flutes / 4 Effective | 4.500 | 2.250 | N/A | 1.000 | SPEB-1511CB | 164T | T-6 |

| Tool Info. .375 W.O.C. |

|||||||||||

| Tool # | D | D-1 | B | Flutes | L | L-1 | L-2 | S | Insert | Screw | Wrench |

| TSK-7537 | .750 | .310 | .375 | 2 Flutes / 1 Effective | 2.750 | 1.000 | .900 | .500 | SPEB-221P | 314T | T-8 |

| TSK-1037 | 1.000 | .350 | .375 | 4 Flutes / 2 Effective | 3.250 | 1.250 | 1.030 | .750 | SPEB-221P | 314T | T-8 |

| TSK-1237 | 1.250 | .510 | .375 | 4 Flutes / 2 Effective | 3.500 | 1.500 | 1.375 | .750 | SPEB-221P | 314T | T-8 |

| TSK-1537 | 1.500 | .575 | .375 | 4 Flutes / 2 Effective | 3.500 | 1.500 | 1.410 | .750 | SPEB-221P | 314T | T-8 |

| TSK-2037 | 2.000 | .750 | .375 | 6 Flutes / 3 Effective | 4.000 | 2.000 | N/A | .750 | SPEB-221P | 314T | T-8 |

| TSK-2537 | 2.500 | .750 | .375 | 6 Flutes / 3 Effective | 4.000 | 2.000 | N/A | .750 | SPEB-221P | 314T | T-8 |

| TSK-3037 | 3.000 | 1.000 | .375 | 6 Flutes / 3 Effective | 4.500 | 2.250 | N/A | 1.000 | SPEB-221P | 314T | T-8 |

| TSK-4037 | 4.000 | 1.250 | .375 | 8 Flutes / 4 Effective | 4.750 | 2.500 | N/A | 1.250 | SPEB-221P | 314T | T-8 |

| Tool Info. .500 W.O.C. |

|||||||||||

| Tool # | D | D-1 | B | Flutes | L | L-1 | L-2 | S | Insert | Screw | Wrench |

| TSK-1550 | 1.500 | .575 | .500 | 4 Flutes / 2 Effective | 3.625 | 1.625 | 1.531 | .750 | SPEB-2522P | 314T | T-8 |

| TSK-2050 | 2.000 | .750 | .500 | 6 Flutes / 3 Effective | 4.125 | 2.125 | N/A | .750 | SPEB-2522P | 314T | T-8 |

| TSK-2550 | 2.500 | .875 | .500 | 6 Flutes / 3 Effective | 4.625 | 2.375 | 2.300 | 1.000 | SPEB-2522P | 314T | T-8 |

| TSK-3050 | 3.000 | 1.000 | .500 | 6 Flutes / 3 Effective | 4.625 | 2.375 | N/A | 1.000 | SPEB-2522P | 314T | T-8 |

| TSK-4050 | 4.000 | 1.250 | .500 | 8 Flutes / 4 Effective | 4.750 | 2.500 | N/A | 1.250 | SPEB-2522P | 314T | T-8 |

| Tool Info. .625 W.O.C. |

|||||||||||

| Tool # | D | D-1 | B | Flutes | L | L-1 | L-2 | S | Insert | Screw | Wrench |

| TSK-1562 | 1.500 | .575 | .625 | 4 Flutes / 2 Effective | 3.750 | 1.750 | 1.650 | .750 | SPEB-322P | 438T | T-10 |

| TSK-2062 | 2.000 | .750 | .625 | 4 Flutes / 2 Effective | 4.250 | 2.250 | N/A | .750 | SPEB-332P | 538T | T-10 |

| TSK-2562 | 2.500 | .875 | .625 | 6 Flutes / 3 Effective | 4.750 | 2.500 | 2.430 | 1.000 | SPEB-332P | 538T | T-10 |

| TSK-3062 | 3.000 | 1.000 | .625 | 6 Flutes / 3 Effective | 4.750 | 2.500 | N/A | 1.000 | SPEB-332P | 538T | T-10 |

| TSK-4062 | 4.000 | 1.250 | .625 | 6 Flutes / 3 Effective | 4.750 | 2.500 | N/A | 1.250 | SPEB-332P | 538T | T-10 |

| Tool Info. .750 W.O.C. |

|||||||||||

| Tool # | D | D-1 | B | Flutes | L | L-1 | L-2 | S | Insert | Screw | Wrench |

| TSK-2075 | 2.000 | .875 | .750 | 4 Flutes / 2 Effective | 4.750 | 2.375 | 2.500 | 1.000 | SPEB-432PA | 638T | T-15 |

| TSK-2575 | 2.500 | 1.000 | .750 | 4 Flutes / 2 Effective | 5.000 | 2.750 | N/A | 1.000 | SPEB-432PA | 638T | T-15 |

| TSK-3075 | 3.000 | 1.000 | .750 | 6 Flutes / 3 Effective | 5.000 | 2.750 | N/A | 1.000 | SPEB-432PA | 638T | T-15 |

| TSK-4075 | 4.000 | 1.250 | .750 | 6 Flutes / 3 Effective | 5.000 | 2.750 | N/A | 1.250 | SPEB-432PA | 638T | T-15 |

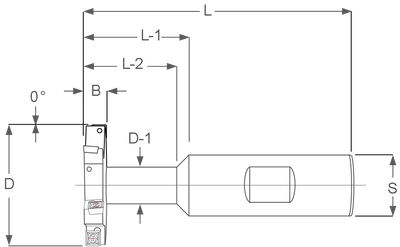

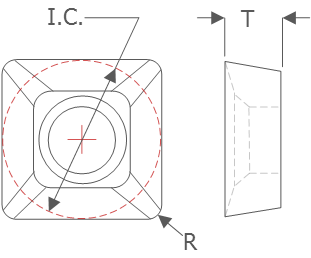

Insert Info

Positive Top & Chipbreaker Inserts

| Insert Info. T-Slot / Key Cutters |

||||

| Insert # | I.C. | T | R | Grades |

| SPEB-1511CB | .187 | .082 | .015 | K11 / K22 |

| SPEB-221P | .250 | .125 | .015 | K11 |

| SPEB-222P | .250 | .125 | .031 | B1M / D66 / K11 / K22 |

| SPEB-2521P | .312 | .125 | .015 | K11 |

| SPEB-2522P | .312 | .125 | .031 | B1M / C55 / K11 / K22 |

| SPEB-321P | .375 | .125 | .015 | K11 |

| SPEB-322P | .375 | .125 | .031 | B1M / D66 / K11 / X40 |

| SPEB-331P | .375 | .187 | .015 | K11 |

| SPEB-332P | .375 | .187 | .031 | B1M / D66 / K11 / K22 |

| SPEB-333P | .375 | .187 | .047 | K11 |

| SPEB-431PA | .500 | .187 | .015 | X33 |

| SPEB-432PA | .500 | .187 | .031 | B1M / D66/ K11 / K22 |

| SPEB-433PA | .500 | .187 | .047 | C55 / X33 |

| SPEB-434PA | .500 | .187 | .062 | K11 / X40 |

Technical data

| Speed and Feed Info. .250 & .312 Width of Cut |

Speed and Feed Info. .375 - .750 Width of Cut |

|||||

| Material | S.F.M. | I.P.T. | Material | S.F.M. | I.P.T. | |

| Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

800 - 1200 | .001 - .002 | Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

800 - 1200 | .002 - .006 | |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .001 - .002 | High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .002 - .005 | |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .001 - .002 | Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .002 - .005 | |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .001 - .002 | Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .002 - .004 | |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .001 - .002 | Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .002 - .004 | |

| Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .001 - .002 | Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .003 - .007 | |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

120 - 180 | .001 - .002 | Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

120 - 180 | .001 - .003 | |

| Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

1000 - 2500 | .0015 - .003 | Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

1000 - 2500 | .003 - .008 | |

| Insert Grade Selection | ||

| Material | Material Examples | Preferred Grade |

| Mild & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | K11 / X33 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | K11 / X33 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | K11 / X33 |

| Tool Steels | A-2, A-6, D-2, M-2 | K11 / X33 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | K11 / X33 |

| Iron | Cast, Nodular | D66 / C55 |

| Iron | Ductile | K11 / X33 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | K11 / X33 |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | K22 or X40 / B1M / K11 / X33 |

| Insert Grade Description | |

| Grade | Description |

| B1M | Uncoated Carbide - No Hone |

| D66 | Multi-Layer Dense Coating |

| C55 | Advanced Multi-Layer PVD Coated Carbide |

| K11 | Universal High Performance Dense Coating |

| X33 | High Performance Nitride |

| K22 | Ultra Smooth Dense Coating - No Hone |

| X40 | Extremely Smooth Boride Coating- No Hone |

| **X33 will be replaced with K11 as stock runs out** |

|

| **C55 will be replaced with D66 as stock runs out** |

|

| **X40 will be replaced with K22 as stock runs out** |

|