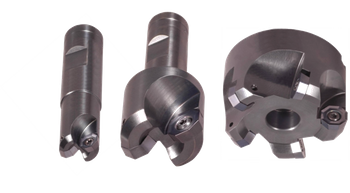

Octa - Mills

- .500 - 6.000 Diameter

- - Extremely Free Cutting

- - Provide Excellent Part Finish

- - 45° lead provides radial chip thinning & reduced tool pressure

- - Several insert grades available

- - OCTA & Round inserts available

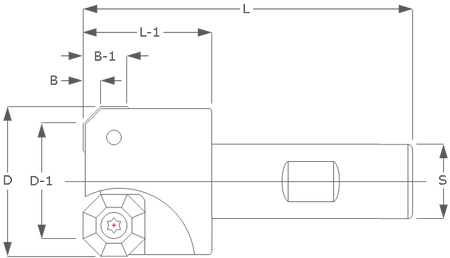

Shank Tools

| Tool Info. Shank Tools |

||||||||||||

| Tool # | D | D-1 | B | B-1 | Flutes | L | L-1 | S | Ramp | Insert | Screw | Wrench |

| OC-500 | .500 | .310 | .095 | .220 | 1 | 3.000 | 1.000 | .625 | Drill * | ODEB-2711 | 5625T | T-10 |

| OC-625 | .625 | .435 | .095 | .220 | 1 | 3.000 | 1.000 | .625 | Drill * | |||

| OC-750 | .750 | .560 | .095 | .220 | 2 | 3.250 | 1.250 | .750 | 25° | ODEB-2721 RDEB-2721 |

5625T | T-10 |

| XOC-750 | .750 | .560 | .095 | .220 | 2 | 5.000 | 3.000 | .750 | 25° | |||

| OC-875 | .875 | .685 | .095 | .220 | 2 | 3.250 | 1.250 | .750 | 15° | |||

| OC-1000 | 1.000 | .810 | .095 | .220 | 3 | 3.500 | 1.500 | .750 | 10° | |||

| XOC-1000 | 1.000 | .810 | .095 | .220 | 3 | 6.250 | 4.000 | 1.000 | 10° | |||

| OC-1250 | 1.250 | 1.062 | .095 | .220 | 3 | 3.500 | 1.500 | .750 | 8° | |||

| OC-1540 | 1.500 | 1.312 | .095 | .220 | 4 | 3.500 | 1.500 | .750 | 6° | |||

| OC-1575 | 1.500 | 1.125 | .160 | .410 | 2 | 3.250 | 1.250 | .750 | 20° | OPEB-535 RPEB-535 |

838T | T-20 |

| OC-1510 | 1.500 | 1.125 | .160 | .410 | 2 | 4.500 | 1.500 | 1.000 | 20° | |||

| XOC-1500 | 1.500 | 1.125 | .160 | .410 | 2 | 8.250 | 6.000 | 1.250 | 20° | |||

| OC-2075 | 2.000 | 1.625 | .160 | .410 | 3 | 3.250 | 1.250 | .750 | 10° | |||

| OC-2010 | 2.000 | 1.625 | .160 | .410 | 3 | 4.500 | 1.500 | 1.000 | 10° | |||

| * Applies to ODEB inserts only | ||||||||||||

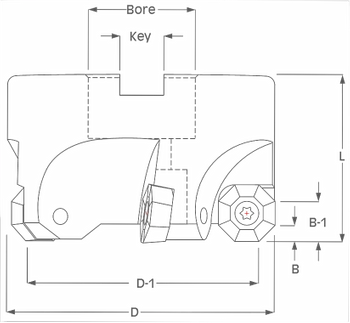

Octa - Shell Mills

| Tool Info. Shell Mills |

||||||||||||

| Tool # | D | D-1 | B | B-1 | L | Flutes | Bore | Key | Ramp | Insert | Screw | Wrench |

| OC-2000 | 2.000 | 1.625 | .160 | .410 | 1.750 | 3 | .750 | .312 | 10° | 838T | T-20 | |

| OC-2500 | 2.500 | 2.125 | .160 | .410 | 1.750 | 4 | 1.000 | .375 | 7° | |||

| OC-3000 | 3.000 | 2.625 | .160 | .410 | 1.750 | 5 | 1.000 | .375 | 5° | OPEB-535 | ||

| OC-4000 | 4.000 | 3.625 | .160 | .410 | 1.750 | 6 | 1.500 | .625 | 3° | RPEB-535 | ||

| OC-5000 | 5.000 | 4.625 | .160 | .410 | 1.750 | 6 | 1.500 | .625 | 2° | |||

| OC-6000 | 6.000 | 5.625 | .160 | .410 | 1.750 | 7 | 1.500 | .625 | 1° | |||

Insert Info.

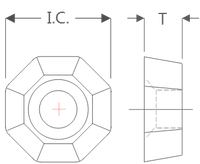

Eight Sided - ODEB & OPEB

| Octa - Positive Top Insert Info. | |||

| Insert # | I.C. | T | Grades |

| ODEB-2711 | .343 | .110 | X33 |

| ODEB-2721 | .343 | .130 | B1M / K11 |

| OPEB-535 | .625 | .220 | K11 / D66 |

| OPEB-535XP | .625 | .220 | B1M / K22 |

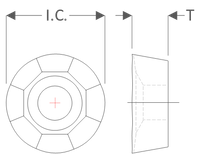

Round - RDEB & RPEB

| Round - Positive Top Insert Info. | |||

| Insert # | I.C. | T | Grades |

| RDEB-2721 | .343 | .130 | K11 |

| RPEB-535 | .625 | .220 | K11 |

Technical Data

| Speed and Feed Info. Octa-Mills |

|||

| Material | S.F.M. | .500 - .750 Dia I.P.T.. |

.875 - 6.000 Dia. I.P.T. |

| Mild

& Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

800 - 1200 | .002 - .005 | .003 - .012 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .002 - .004 | .003 - .010 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .002 - .004 | .003 - .010 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .002 - .004 | .003 - .010 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .002 - .003 | .002 - .007 |

| Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .003 - .006 | .004 - .012 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

120 - 180 | .001 - .003 | .001 - .004 |

| Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

1000 - 2500 | .003 - .006 | .004 - .014 |

| Insert Grade Selection Octa-Mills |

||

| Material | Material Examples | Preferred Grades |

| Mild & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | X33 or K11 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | X33 or K11 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | X33 or K11 |

| Tool Steels | A-2, A-6, D-2, M-2 | X33 or K11 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | X33 or K11 |

| Iron | Cast, Nodular | D66 / X33 or K11 |

| Iron | Ductile | X33 or K11 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | X33 or K11 |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | K22 / B1M |

| Insert Grade Descriptions Octa-Mills |

|

| Grade | Description |

| B1M | Uncoated Carbide - No Hone |

| D66 | Multi-Layer Dense Coating |

| K11 | Universal High Performance Dense Coating |

| X33 | High Performance Nitride Coating |

| K22 | Ultra Smooth Dense Coating - No Hone |

| **X33 will pe replaced with K11 as stock runs out** |

|