Button Cutters - Series #2

.625 - 1.000 Diameter

- - Radial chip thinning allows higher feed rates

- - Extremely free cutting ground positive top inserts

- - Molded inserts also available

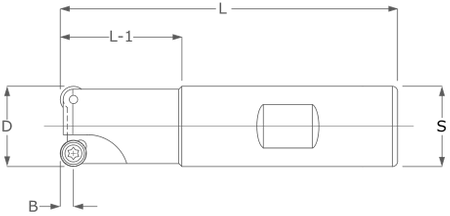

| Tool Info. Series #2 Button Cutters |

||||||||||||

| Tool # | D | B | Flutes | L | L-1 | S | Plunge | Ramp | Ground Insert | Molded Insert | Screw | Wrench |

| BC2-625L | .625 | .125 | 2 | 3.875 | .970 | .750 | .015 | 3° | RCEB-22G | RCEB-22 | 314T | T-8 |

| BC2-750 | .750 | .125 | 2 | 3.125 | 1.125 | .750 | .020 | 3° | ||||

| BC2-750L | .750 | .125 | 2 | 4.250 | 2.250 | .750 | .020 | 3° | ||||

| BC2-750XL | .750 | .125 | 2 | 5.750 | 3.750 | .750 | .020 | 3° | ||||

| BC2-1000L | 1.000 | .125 | 2 | 5.250 | 3.000 | 1.000 | .045 | 4° | ||||

| BC2-1000XL | 1.000 | .125 | 2 | 7.250 | 5.000 | 1.000 | .045 | 4° | ||||

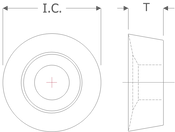

Insert Info.

Ground Insert

- Ground inserts will reduce tool pressure & provide a better finish over molded inserts.

| Insert Info. .250 I.C. - Ground |

|||

| Insert # | I.C. | T | Grades |

| RCEB-22G | .250 | .125 | B1M / X33 / X40 |

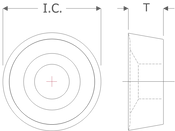

Molded Insert

- Molded inserts will provide reduced cutting pressure over a square shoulder mill without the cost of a ground insert.

| Insert Info. .250 I.C. - Molded |

|||

| Insert # | I.C. | T | Grades |

| RCEB-22 | .250 | .125 | X33 / A10M |

Technical Data

| Speed and Feed Info. Series #2 Button Cutters |

|||

| Material | S.F.M. | .625 - .750 Dia. I.P.T. |

1.000 Dia. I.P.T. |

| Mild

& Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

800 - 1200 | .002 - .005 | .003 - .012 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .002 - .004 | .003 - .010 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .002 - .004 | .003 - .010 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .002 - .004 | .003 - .010 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .002 - .003 | .002 - .007 |

| Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .003 - .006 | .004 - .012 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

120 - 180 | .001 - .003 | .001 - .004 |

| Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

1000 - 2500 | .003 - .006 | .004 - .014 |

| Insert Grade Selection RCEB ( Ground Inserts ) |

||

| Material | Material Examples | Preferred Grade |

| High & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | X33 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | X33 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | X33 |

| Tool Steels | A-2, A-6, D-2, M-2 | X33 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | X33 |

| Iron | Cast, Nodular | X33 |

| Iron | Ductile | X33 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | X33 |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | X40 / B1M |

| Insert Grade Selection RCEB ( Molded Inserts ) |

||

| Material | Material Examples | Preferred Grade |

| High & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | X33 / A10M |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | X33 / A10M |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | X33 / A10M |

| Tool Steels | A-2, A-6, D-2, M-2 | X33 / A10M |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | X33 / A10M |

| Iron | Cast, Nodular | X33 / A10M |

| Iron | Ductile | X33 / A10M |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | X33 / A10M |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | X33 / A10M |

| Insert Grade Description RCEB Inserts |

|

| Grade | Description |

| A10M | TIALN / TIN Coated Carbide |

| X33 | High Performance Nitride Coating |

| B1M | Uncoated Carbide - No Hone |

| X40 | Extremely Smooth Boride Coating |