Adjustable Chamfer Mills

Shank Tools - Shell Mills - Reversed Shank Tools

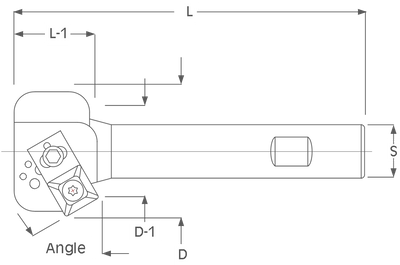

Shank Tools

- - Simple - Accurate - Versatile - Economical

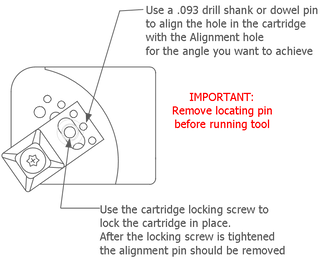

- - Predetermined alignment holes for: 0° - 15° - 30° - 45° - 60° - 75°

- - Use an .093 dowel pin to align the align the holes for the predetermined angles

- - Tighten cartridge lock screw, remove alignment pin and the tool is ready to go

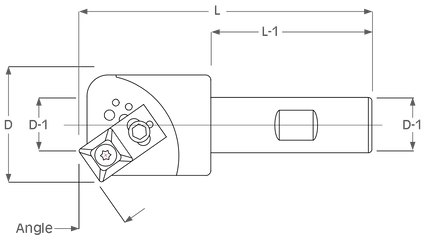

| Tool Info. Adjustable Chamfer Mills - Shank Style |

|||||||

| Tool # | Flutes | L | L-1 | S | Cartridge | Cartridge Screw | Insert |

| AC-750 | 1 | 3 | 1.000 | .750 | AC2-Cart | 25638 | SDEB-2151P |

| AC-1250 | 1 | 3.5 | 1.500 | .750 | AC-Cart | 83212 | SPEB-422PA |

| AC-1500 | 1 | 3.5 | 1.500 | .750 | |||

- Alignment holes for 6 common chamfer angles or achieve any angle with a comparator

| AC Shank Tools - Standard

Preset Angle Dimensions Angle Dimensions Referenced From Face Of Tool |

||||||||||||

| Preset Angle | 0° | 15° | 30° | 45° | 60° | 75° | ||||||

| Tool # | D | D-1 | D | D-1 | D | D-1 | D | D-1 | D | D-1 | D | D-1 |

| AC-750 | .750 | - | .770 | .350 | .810 | .420 | .820 | .520 | .810 | .600 | .790 | .680 |

| AC-1250 | 1.250 | - | 1.310 | .450 | 1.390 | .590 | 1.430 | .790 | 1.390 | .970 | 1.350 | 1.120 |

| AC-1500 | 1.500 | - | 1.560 | .700 | 1.640 | .840 | 1.680 | 1.040 | 1.640 | 1.220 | 1.600 | 1.370 |

| - Achieve Any Angle With A Comparator - | ||||||||||||

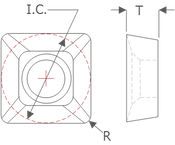

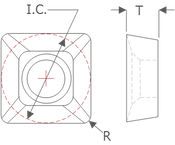

| Insert Info. Adjustable Chamfer Mill - Shank Tool |

||||||

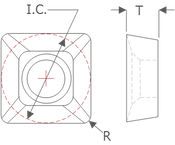

| Insert # | I.C. | T | R | Screw | Wrench | Grade |

| SDEB-2151P | .250 | .093 | .015 | 300T | T-8 | K11 |

| SPEB-422PA | .500 | .125 | .031 | 614T | T-15 | K11 |

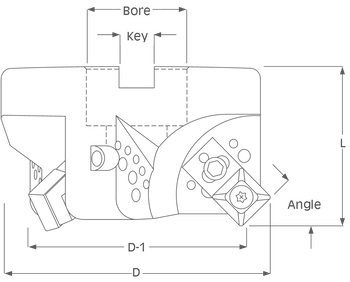

Shell Mills

- Multiple Flutes For Higher Feed Rates

| Tool Info. Adjustable Chamfer Mill - Shell Mount |

|||||||

| Tool # | Flutes | L | Bore | Key | Cartridge | Cartridge Screw | Insert |

| AC-3000 | 3 | 1.625 | 1.000 | .375 | AC3-Cart | 83234 | SPEB-432PA |

- Alignment holes for 6 common chamfer angles or achieve any angle with a comparator

| AC Shell Mill - Standard

Preset Angle Dimensions Angle Dimensions Referenced From Face Of Tool |

||||||||||||

| Preset Angle | 0° | 15° | 30° | 45° | 60° | 75° | ||||||

| Tool # | D | D-1 | D | D-1 | D | D-1 | D | D-1 | D | D-1 | D | D-1 |

| AC-3000 | 3.000 | - | 3.080 | 2.250 | 3.180 | 2.440 | 3.220 | 2.620 | 3.210 | 2.780 | 3.160 | 2.940 |

| - Achieve Any Angle With A Comparator - | ||||||||||||

| Insert Info. Adjustable Chamfer Tool - Shell Mount |

||||||

| Insert # | I.C. | T | R | Screw | Wrench | Grades |

| SPEB-432PA | .500 | .187 | .031 | 638T | T-15 | B1M / D66 / K11 / X40 |

Adjustable Chamfer Mills Reversed

| Tool Info. Adjustable Chamfer Mills Reversed |

|||||||

| Tool # | Flutes | L | L-1 | S | Cartridge | Cartridge Screw | Insert |

| ACR-1500 | 1 | 4.500 | 1.000 | .750 | AC-Cart | 83212 | SPEB-422PA |

- Alignment holes for 6 common chamfer angles or achieve any angle with a comparator

| ACR Shank Tools -

Standard Preset Angle Dimensions Angle Dimensions Referenced From Back Face Of Tool |

||||||||||||

| Preset Angle | 0° | 15° | 30° | 45° | 60° | 75° | ||||||

| Tool # | D | D-1 | D | D-1 | D | D-1 | D | D-1 | D | D-1 | D | D-1 |

| ACR-1500 | 1.500 | - | 1.560 | .700 | 1.640 | .840 | 1.680 | 1.040 | 1.640 | 1.220 | 1.600 | 1.370 |

| - Achieve Any Angle With A Comparator - | ||||||||||||

| Insert Info. Adjustable Chamfer Mill Reverse |

||||||

| Insert # | I.C. | T | R | Screw | Wrench | Grades |

| SPEB-422PA | .500 | .125 | .031 | 614T | T-15 | K11 |

Technical Data

| Speed and Feed Info. Adjustable Chamfer Mills Adjustable Chamfer Mills Reversed |

||

| Material | S.F.M. | I.P.T. |

| Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

800 - 1200 | .002 - .005 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .002 - .004 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .002 - .004 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .002 - .004 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .002 - .004 |

| Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .003 - .007 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

120 - 180 | .001 - .002 |

| Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

1000 - 2500 | .003 - .007 |

| Insert Grade Selection AC & ACR Adjustable ChamferMills |

||

| Material | Material Examples | Preferred Grade |

| High & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | K11 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | K11 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | K11 |

| Tool Steels | A-2, A-6, D-2, M-2 | K11 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | K11 |

| Iron | Cast, Nodular | D66 / K11 |

| Iron | Ductile | K11 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | K11 |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | B1M / K22 or X40 / K11 |

| Insert Grade Description | |

| Grade | Description |

| B1M | Uncoated Carbide - No Hone |

| D66 | Multi-Layer Dense Coating |

| K11 | High Performance Nitride Coating |

| K22 | Ultra Smooth Dense Coating |

| X40 | Extremely Smooth Boride Coating |

| **X40 will be replaced with K22 as inventory runs out ** |

|