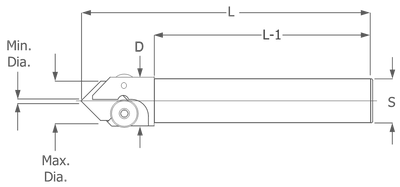

90° Spot Drills

Patent# 5,259,707

- - 2 Flutes Effective

- - Must be held in a Collet

| Tool Info. 90° Spot Drills |

|||||||||

| Tool # | Min Dia. | Max Dia. | L | L-1 | S | D | Clamp | Screw | Insert |

| SDCS-90 | .070 | .390 | 3.250 | 2.500 | .375 | .430 | 180310 | 25618 | 90 |

| SDCS-900 | .093 | .470 | 3.250 | 2.375 | .500 | .625 | 311205 | 44025 | 900 |

| SDCS-901 | .156 | .600 | 3.060 | 2.000 | .500 | 1.000 | 501912 | 103212 | 901 |

| SDCS-901L | .156 | .600 | 5.330 | 4.250 | .750 | ||||

| SDCS-902 | .250 | .900 | 4.130 | 2.500 | .750 | 1.125 | 621915 | 103212 | 902 |

| SDCS-902L | .250 | .900 | 6.530 | 4.875 | 1.000 | ||||

| SDCS-9025 | .250 | 1.270 | 4.690 | 2.625 | 1.000 | 1.250 | 621915 | 103212 | 9025 |

| SDCS-903 | .375 | 1.560 | 4.880 | 2.625 | 1.000 | 1.700 | 102518 | 142812 | 903 |

Insert Info.

| Insert Info. 90° Spot Drills |

|||

| Insert | Grades | ||

| 90 | A1M | ||

| 900 | A1M | ||

| 901 | A1M | ||

| 901CB | A1M | ||

| 902 | A1M | ||

| 902CB | A1M / CPM4 | ||

| 9025 | A1M | ||

| 9025CB | A1M | ||

| 903 | A1M | ||

| 903CB | CPM4 | ||

Technical Data

Insert Loading Procedure

- Air Blast Pocket Clean

- Hold Insert in place (Chisel points to front & rear)

- - Flatted corners are to prevent loading insert backwards

- Tighten clamps until each one makes light contact

- Alternate tightening screws several times until screws are tight

| Speed and Feed

Info. Spot Drills |

||

| Material | S.F.M. | I.P.R. |

| Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

500 - 700 | .0024 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

400 - 600 | .0016 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 600 | .002 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .002 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

200 - 400 | .0014 |

| Iron Ex. Cast, Ductile, Nodular |

400 - 700 | .004 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

120 - 250 | .0012 |

| Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

1000 - 2000 | .006 |

| Insert Grade Selection 90° Spot Drills |

||

| Material | Material Examples | Preferred Grade |

| Mild & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | A1M |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | A1M |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | A1M |

| Tool Steels | A-2, A-6, D-2, M-2 | A1M |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | A1M |

| Iron | Cast, Ductile, Nodular | A1M |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | A1M |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | A1M |

| Insert Grade Description 90° Spot Drills |

|

| Grade | Description |

| A1M | Tin Coated |

| CPM4 | High Speed Steel Insert |