.500 - 1.187 Dia. Back Counterbore Tools

- Counterbore without moving your part

- Easy to program and use :

- Offset tool

- Enter hole

- Return to center

- Plunge Counterbore to depth

- Retract from cut

- Offset tool

- Exit part

Back Counterbore Demonstration Video

Coolant thru can be added to any BCB in 2 - 3 working days

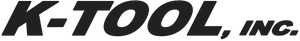

| Tool Info. .500 - 1.187 Dia. Back Counterbore Tool |

||||||||||

| Tool # | S.H.C.S. Size | Flutes | D | L | L-1 | D.O.C | S | Insert | Screw | Wrench |

| BCB-500 | .313 | 1 | .500 | 2.937 | 1.187 | .750 | .500 | SPEB-1511CB | 164T | T-6 |

| BCB-594 | .375 | 1 | .594 | 2.937 | 1.187 | .750 | .500 | |||

| BCB-687 | .438 | 1 | .687 | 3.625 | 1.625 | 1.000 | .750 | SPEB-221CB | 300T | T-8 |

| BCB-781 | .500 | 1 | .781 | 3.812 | 1.812 | 1.250 | .750 | SPEB-221CB | 314T | T-8 |

| BCB-1000 | .625 | 1 | 1.000 | 4.562 | 2.312 | 1.625 | 1.000 | |||

| BCB-1187 | .750 | 1 | 1.187 | 4.812 | 2.562 | 1.937 | 1.000 | |||

| Tool # | Min.

Existing Hole Diameter |

Offset to

Enter Hole |

| BCB-500 | .320 | .100 |

| BCB-594 | .390 | .110 |

| BCB-687 | .450 | .120 |

| BCB-781 | .510 | .135 |

| BCB-1000 | .640 | .180 |

| BCB-1187 | .800 | .195 |

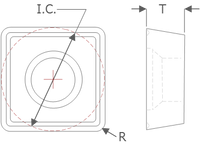

Insert Info.

| Insert Info. .500 - 1.187 Back Counterbore Tool |

||||

| Insert # | I.C. | T | R | Grades |

| SPEB-1511CB | .187 | .082 | .015 | K11 / K22 |

| SPEB-221CB | .250 | .125 | .015 | K11 / K22 |

Technical Data

| Speed and Feed Info. .500 - 1.187 Back CounterBore Tool |

||

| Material | S.F.M. | I.P.R. |

| Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

800 - 1200 | .002 - .003 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .002 - .003 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .002 - .003 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .001 - .003 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .001 - .002 |

| Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .002 - .003 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

120 - 180 | .001 - .002 |

| Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

1000 - 2500 | .002 - .003 |

| Insert Grade Selection | ||

| Material | Material Examples | Preferred Grade |

| High & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | K11 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | K11 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | K11 |

| Tool Steels | A-2, A-6, D-2, M-2 | K11 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | K11 |

| Iron | Cast | K11 |

| Iron | Ductile, Nodular | K11 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | K11 |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | K22 / K11 |

| Insert Grade Description | |

| Grade | Description |

| K11 | Universal High Performance Dense Nitride Coating |

| K22 | Ultra Smooth Dense Coating - No Hone |