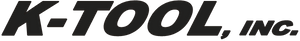

1.156 - 1.375 Diameter Flat Bottom Drills

Available in 2:1 & 3:1 Ratio

- - Cuts a flat bottom within .001

- - Coolant Thru - Side & Rear Ports

- - Helical flute design

- - Uses the same insert in both pockets

- - 4 cutting edges per insert

| Tool Info. 1.156 Dia. - 1.375 Dia. Flat Bottom Drills |

||||||||||

| Tool # | D | Flutes | L | L-1 | D.O.C. | S | Coolant Plug | Inserts | Screw | Wrench |

| FB-1156 | 1.156 | 2-1 Effective | 6.000 | 3.750 | 2.312 | 1.250 | NPT 1/4 | SPEB-332CB or SPEB-332P |

538T | T-10 |

| FB-1156-3 | 1.156 | 2-1 Effective | 7.125 | 4.875 | 3.468 | |||||

| FB-1187 | 1.187 | 2-1 Effective | 6.000 | 3.750 | 2.375 | |||||

| FB-1187-3 | 1.187 | 2-1 Effective | 7.125 | 4.875 | 3.562 | |||||

| FB-1250 | 1.250 | 2-1 Effective | 6.000 | 3.750 | 2.500 | |||||

| FB-1250-3 | 1.250 | 2-1 Effective | 7.500 | 5.250 | 3.750 | |||||

| FB-1281 | 1.281 | 2-1 Effective | 6.000 | 3.750 | 2.562 | |||||

| FB-1281-3 | 1.281 | 2-1 Effective | 6.000 | 3.750 | 3.843 | |||||

| FB-1312 | 1.312 | 2-1 Effective | 6.000 | 3.750 | 2.625 | |||||

| FB-1312-3 | 1.312 | 2-1 Effective | 7.562 | 5.312 | 3.937 | |||||

| FB-1375 | 1.375 | 2-1 Effective | 6.000 | 3.750 | 2.750 | |||||

| FB-1375-3 | 1.375 | 2-1 Effective | 7.625 | 5.375 | 4.125 | |||||

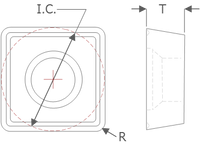

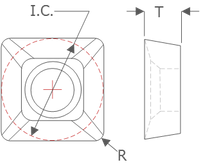

Insert Info.

Chipbreaker & Positive Top Inserts

| Insert Info. 1.156 - 1.375 Dia. Flat Bottom Drills |

||||

| SPEB-332CB | SPEB-332P | |||

| Grades | K11 / K22 | Grade | D66 | |

| I.C. | .375 | I.C. | .375 | |

| T | .187 | T | .187 | |

| R | .031 | R | .031 | |

Technical Data

| Speed and Feed Info. 1.156 - 1.375 Dia. Flat Bottom Drills |

||

| Material | S.F.M. | I.P.R. |

| Mild & Low Carbon Steel Ex. 1018, 1020, 1117, 1141, 12L14 |

800 - 1200 | .003 - .005 |

| High

Carbon & Alloy Steel Ex. 1045, 4140, 4340, 52100, 8620 |

500 - 800 | .003 - .005 |

| Lower

Carbon Tool Steel Ex. P-20, H-13, S-7 |

400 - 700 | .003 - .005 |

| Tool

Steel Ex. A-2, A-6, D-2, M-2 |

300 - 600 | .002 - .004 |

| Stainless

Steel Ex. 304, 316, 420, 15-5PH, 17-4PH |

300 - 600 | .002 - .004 |

| Iron Ex. Cast, Ductile, Nodular |

600 - 1000 | .003 - .006 |

| Nickel

& Titanium Alloy Ex. Inconel, Hastelloy, TI-6AL-4V |

120 - 180 | .002 - .003 |

| Non-Ferrous

Metal Ex. Aluminum, Bronze, Brass |

1000 - 2500 | .004 - .008 |

| Insert Grade Selection Flat Bottom Drills |

||

| Material | Material Examples | Preferred Grade |

| Mild & Low Carbon Steels | 1018, 1020, 1117, 1141, 12L14 | K11 |

| High Carbon & Alloy Steels | 1045, 4140, 4340, 52100, 8620 | K11 |

| Lower Carbon Tool Steels | P-20, H-13, S-7 | K11 |

| Tool Steels | A-2, A-6, D-2, M-2 | K11 |

| Stainless Steels | 303, 304, 316, 420, 15-5PH, 17-4PH | K11 |

| Iron | Cast | D66 / K11 |

| Iron | Ductile, Nodular | K11 |

| Nickel & Titanium Alloys | Inconel, Hastelloy, TI-6AL-4V | K11 |

| Non-Ferrous Metals | Aluminum, Bronze, Brass | K22 / K11 |

| Insert Grade Description | |

| Grade | Description |

| D66 | Multi-Layer Dense Coating |

| K11 | Universal High Performance Dense Coating |

| K22 | Ultra Smooth Dense Coating - No Hone |

***Important***

- To maintain correct drill diameter in lathe applications

- indicate the drill to spindle center